Making Progress

After having 3 different 4oz. samples mixed, we've decided on a color ( even though bodywork won't start til spring, we were anxious....not to mention we have a Fujimi model kit to paint). The color is a solid, Acrylic enamel, and is NOT red! Hard to tell from the photo, but the blue has a lot of purple in it - very close in color to a WD-40 can. Solid color will make touching up stone chips, etc. easy.

I bought a wheel polishing kit, some self-etching primer, and some Argent Silver wheel paint from Eastwood. The wheels I got cheap on Ebay cleaned up real "purdy". Bought Falken Azenis tires from Vulcan Tire - 195/60-14, and had them mounted up so I can check body fit, and frame / engine attitude.

I finally found the 1990 GM full size truck bell housing I was searching for - the Camaro b/h had the transmission tilted at a 19 degree angle, and had the hydraulic throw-out sticking way out on the driver's side. The truck b/h still has a hyd. t/o, but its on the passenger side, under the starter. Much better fit into the tranny tunnel. Had to make a "Frankenstein" shifter, grafting the center shifter portion of a a Mustang shifter into the Camaro shifter base plate. A short throw Mustang shift lever puts the knob exactly where it needs to be!

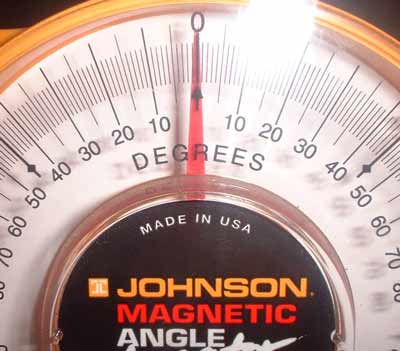

Since the tranny is now upright, the mounting pad is clocked 19 degrees relative to the C/L. I had to fabricate a mounting bracket that would rotate the mount back to vertical, and offset forward. Only draw back is that after the initial fill, out of the chassis, changing tranny fluid will require jacking up one side of the car to tip the tranny to that 19 deg. angle....

Note my shop buddy Roscoe ( also know as dumb-ass-dog), taking a break from barking at grinder sparks....he is brown and white - seriously needs a bath after every outing.

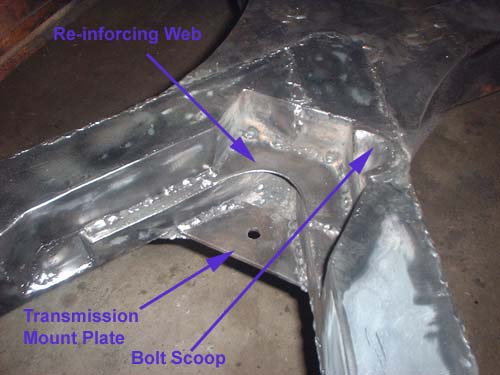

After cutting open the X-member ( take a deep breadth and fire up the torches), many, many tests fits of block and trans were done, then Sydney, my "Ace" mechanic assisted in making up a cardboard template for the sheetmetal work. The modfication has the same internal box structure as the original, with added internal gussets corresponding to the external "web". Will be as stiff or stiffer than the original. On the right hand side, I needed more clearance for one bolt head, so I used half a piece of tubing to create a scoop, so as not to compromise my box section.

The MIG welds aren't as pretty as they could be, but there's good penetration - checked by spot grinding some areas and re-welding afterwards.

I've got a good 1/2" of clearance all the way around the tranny, with more in the direction of rotation due to torque.

Many trial fits with various blocking were needed to set the engine / trans in the right position so the engine is as far back as the distributor will allow, so the hood will close with the manifold, carb, and air-cleaner installed. Before finalizing the X-member and motor mounts, great consideration was given to driveline phasing. Final position results in less than 1/2 degree difference between tail shaft and pinion C/L's, and the shafts are offset both vertically and laterally - blind man'd pay a million bucks........